ESD electrostatic discharge overview

When a charged object comes into contact with another object at a different potential, the charges between the two objects equalize. The voltage v(t) and current i(t) transients when this occurs are shown below. The amplitude and waveform of the transient depend on the voltage difference and total impedance in the current path. The pulses will be induced and may produce signals that may affect nearby electronic circuits. If the discharge current through the product attempts to take a path that includes an air gap, a secondary discharge may occur within the device. The voltage across the gap increases until the gap fails.

Some steps to avoid ESD issues in your design:

a) Select a circuit configuration that is unresponsive to short transients.

b) Lay out the PCB pattern to minimize induced voltages at critical nodes.

c) Prevent unavoidable discharge transients from coupling into circuits and cables.

d) Design enclosures wherever possible to prevent emissions from occurring.

ESD testing complies with IEC61000-4-2

IEC61000-4-2 is the standard for immunity ESD testing. It applies a defined current waveform at a specified voltage level from a handheld generator called an ESD gun. It uses a capacitor supplied by a high-voltage power supply, whose charged voltage is discharged through a series impedance through the contacts to ground. Two discharge methods are used. They are contact discharge and air discharge.

ESD Test-Contact Discharge

In the contact discharge method, stress can be applied directly to the EUT or to the coupling plane adjacent to the EUT. Before each test pulse, the capacitor is charged to the required level, but its voltage is held at the generator’s probe via a vacuum relay. Apply the probe to an appropriately chosen point on the EUT or coupling plane. The generator is then triggered, causing the relay contacts to close and the capacitor voltage to be applied to the EUT through the probe. This creates a current pulse when voltage discharges through the combined series impedance of the generator, EUT and ground plane. Repeat the movement the desired number of times with appropriate polarity and level in each position.

ESD test-air discharge

The same generator is used for the air discharge method, but with a rounded rather than pointed probe tip. The capacitor is charged to the desired level as before, but the voltage is now continuously applied to the probe, which is located away from the EUT. For each test pulse, the tip is subtly raised to a selected point on the EUT until it makes contact. Just before this happens, the air gap between the tip and the EUT will breakdown and the discharge current will flow, limited as mentioned before by the combined series impedance of the generator, air gap, EUT and return path. Again, repeat the movement the desired number of times with appropriate polarity and level in each position.

Electrostatic discharge ESD test layout

ESD pulses have sub-nanosecond rise times, so RF layout precautions are critical.

1. The test must recreate the actual fast rise time found as this is an important parameter that determines the path of the discharge through the EUT and the response of the EUT itself. The Ground Reference Plane (GRP) is an integral part of the setup to which the return lead of the generator must be well connected as this connection forms part of the current return path.

2. The indirect discharge part of the test uses two other planes different from GRP, called horizontal coupling plane (HCP) and vertical coupling plane (VCP). The discharges from these aircraft simulate the stresses generated from real-life radiation fields emitted to nearby objects.

3. Each coupling plane is connected to the GRP via resistive leads to ensure any charge flows out within a few microseconds. The construction of these leads is critical: each end should be close to a resistor so that the length of lead between them is isolated from the connection and stray coupling from it is neutralized.

4. Although the power rating is not important, the resistor itself should be able to withstand high pulse dV/dt without damage, so the carbon composition type is suitable.

5. For ESD events of tens of nanoseconds, the plane carries the full stress voltage, which is capacitively coupled to the EUT. Any stray capacitance from the plane to objects other than the EUT will modify the plane’s voltage and current waveforms, thereby modifying the applied stress.

6. Therefore, it is important to maintain at least 1 meter of clear space around the EUT, which means the tabletop setup has some separation from walls or other objects.

7. Likewise, separation from the VCP to the EUT is specified as 10cm; even small changes in this distance can cause large changes in coupling to the EUT, so convenient methods of controlling it, such as plastic 10cm spacers on planar surfaces, is helpful.

More information

Semiware provides a full range of ESD electrostatic protection devices and provides customers with a complete ESD testing environment. We have EMC electromagnetic compatibility laboratories and excellent EMC engineers at home and abroad to provide you with services at any time. For more information, please visit the Semiware page: https://semiware.com/

About Semiware

Semiware has a comprehensive product lineup of overvoltage protection device families. The company leverages its technology in the semiconductor field and application background in end products to serve customers in the electronics, automotive and industrial markets. If you have technical questions, please contact the technical support team as follows:

Email: fae01@semiware.com;

Phone: 86-21-3463-7654;

Toll-free technical support hotline: 400-021-5756;

For more information, please visit semiware official website: https://semiware.com

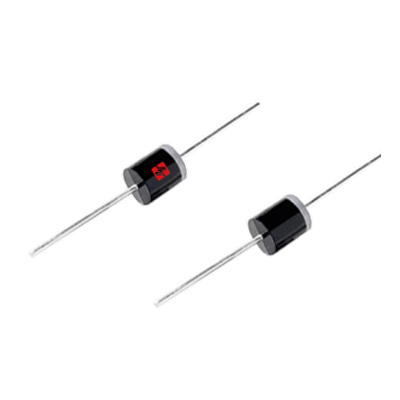

Automotive TVSs

Automotive TVSs General TVS Diodes

General TVS Diodes High Reliability TVSs

High Reliability TVSs High Current TVSs

High Current TVSs Automotive ESDs

Automotive ESDs TVS Diodes Array

TVS Diodes Array MLVs

MLVs Polymers

Polymers High Reliability

High Reliability General Thyritors

General Thyritors Programmable Series

Programmable Series Automotive PLEDs

Automotive PLEDs Pled Protectors

Pled Protectors General Gas Tubes

General Gas Tubes Automotive GDTs

Automotive GDTs Glass Discharge Tubes

Glass Discharge Tubes General Varistors

General Varistors Sensitive SCRs

Sensitive SCRs SCRs

SCRs Triacs

Triacs 4-Quadrant Triacs

4-Quadrant Triacs Small Signal Mosfets

Small Signal Mosfets Power Mosfets

Power Mosfets Transistors

Transistors Bridge Rectifiers

Bridge Rectifiers Schottky Rectifiers

Schottky Rectifiers Switching Diodes

Switching Diodes Fast Recovery Diodes

Fast Recovery Diodes Rectifier Diodes

Rectifier Diodes Fast Recovery Diodes

Fast Recovery Diodes PTC

PTC Energy Storage

Energy Storage Vehicle Adapter

Vehicle Adapter Media Hub

Media Hub Interior Light

Interior Light Head Lighting

Head Lighting DC Charger

DC Charger PTC

PTC AC Charger

AC Charger BMS

BMS ADAS

ADAS BCM

BCM xDSL

xDSL Outdoor AP

Outdoor AP Set-top Box

Set-top Box PBX

PBX RRU

RRU BBU

BBU Power Supply

Power Supply Small Cell

Small Cell Cellular Base Station

Cellular Base Station IP Camera

IP Camera Security Camera

Security Camera NVR

NVR DVR

DVR Two-wheeler locator

Two-wheeler locator POS

POS VR

VR UAV

UAV E-Bike

E-Bike PC

PC Pad

Pad Smart Lock

Smart Lock Mobile Phone

Mobile Phone Smart Watch

Smart Watch E-Cigarette

E-Cigarette TWS

TWS PV Inverter

PV Inverter Energy Storage

Energy Storage DC-DC Module

DC-DC Module Power Bank

Power Bank Fast Charging

Fast Charging Adapter

Adapter ECG monitor

ECG monitor Sphygmomanometer

Sphygmomanometer Electronic Scale

Electronic Scale Radiography

Radiography Exergen

Exergen Blood Glucose Meter

Blood Glucose Meter DC Motor

DC Motor PLC

PLC Smart Metering

Smart Metering Sensor

Sensor Power Line Carrier

Power Line Carrier Electricity Meter

Electricity Meter Elevator Call Board

Elevator Call Board Traffic Lighting

Traffic Lighting Solar Lighting

Solar Lighting Smart Lamps

Smart Lamps Led Lighting

Led Lighting StreetLight Controller

StreetLight Controller Dishwasher

Dishwasher Sweeping Robot

Sweeping Robot Smart TV

Smart TV Washing Machine

Washing Machine Smart Speaker

Smart Speaker Coffee Maker

Coffee Maker Buttons/Switches

Buttons/Switches LIN

LIN DC12V-P5a

DC12V-P5a NFC

NFC MIC

MIC Audio

Audio GPS

GPS RJ11

RJ11 POE-10G-6KV

POE-10G-6KV Type-C

Type-C VGA

VGA USB2.0-Dual

USB2.0-Dual RS232-ESD

RS232-ESD HDMI

HDMI eSATA

eSATA USB3.0

USB3.0 AC220V-5KA

AC220V-5KA Semiware's over 300 interface protection solutions cover automotive electronics, industrial control, consumer electronics, and other industry sectors.

Semiware's over 300 interface protection solutions cover automotive electronics, industrial control, consumer electronics, and other industry sectors. To become an excellent comprehensive service provider of circuit protection solutions.

To become an excellent comprehensive service provider of circuit protection solutions. To become an excellent comprehensive service provider of circuit protection solutions.

To become an excellent comprehensive service provider of circuit protection solutions.

简体中文

简体中文